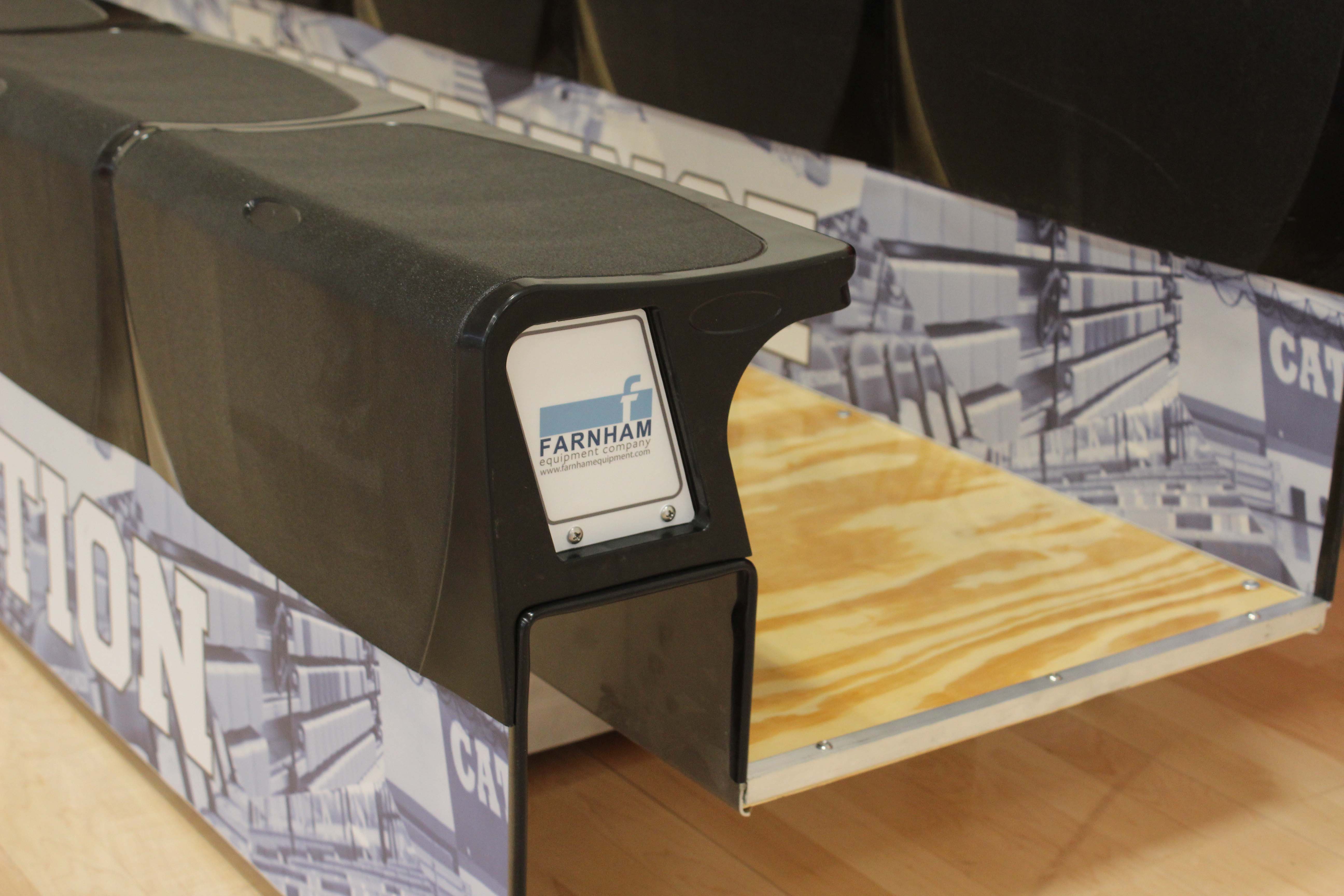

Auditorium Seating

Big Walnut High School: Big and Brand New

Project Name: Big Walnut High SchoolOwner: Big Walnut Local SchoolsArchitect: VSWC ArchitectsCMR: Gilbane Construction CompanyScope: Provide and Install Educational Casework, Telescopic Seating, Auditorium Seating, Science Lab CaseworkCompletion Date: December 2021 Back in 2017, the Big Walnut Local School District passed a bond levy to build a new high school for Read more…