The Importance of Regular Inspections

This article is meant to inform customers of what benefits come from having annual maintenance inspections performed by certified personnel.

Required, Not Recommended

Farnham Equipment Company (FEC) is proud to say that it performs over 1,000 annual inspections each year. However, that is quite conservative when considering adding the state of Michigan to our line of work recently. For the FEC Service Department, everything begins and ends with the comprehensive inspections FEC-certified installers perform on customers’ equipment.

The primary reason for perforation inspections for gymnasium seating, athletic equipment, and outdoor bleachers & grandstands is that annual inspections are required. By having annual inspections performed, customers eliminate unnecessary liability risks for students and spectators. Having annual inspections performed aligns with FEC’s mission to help customers increase the life cycle of their equipment. The basis of FEC’s recommendation for yearly inspections comes from multiple codes of compliance, including:

- Building Standards Ohio Administrative Code 4101:1-01

- Ohio Building Code 2024 , as required in Chapter 10, Section 1030.1.1

- ICC 300-17

- IBC-21

- Title 37 Health-Safety Morals, Ohio Revised Code, Chapter 3781.06

There is certainly overlap between some of these codes and standards, but FEC believes that these standards regarding inspections for facilities are required to be followed. Due to the numerous hazards that can present themselves on customer equipment during its life cycle, these regular assessments help avoid further liabilities by addressing potential repairs and preventative maintenance.

What Can Customers Anticipate With A FEC Inspection?

To give customers the fullest insight into the state of their equipment, FEC’s inspections are quite comprehensive in scope. As previously mentioned, the inspections offered include telescopic seating, athletic equipment and outdoor bleachers & grandstands. These inspections do not change in scope, regardless of the size of the facility being inspected. After the inspections, customers will receive customized inspection reports detailing the state of various parts of their equipment, along with recommendations and, eventually, quotations for that work.

Inspections include, but are not limited to:

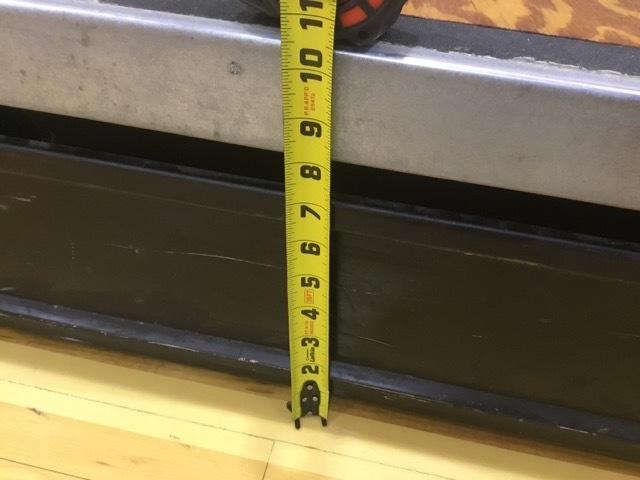

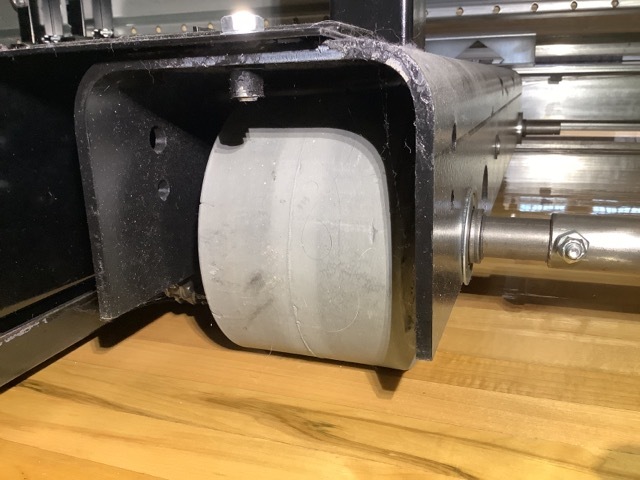

- Assessment of the overall structural integrity of all equipment framework

- Determination of code compliance issues

- Identification of unnecessary liability risks

- Operation of equipment for proper function

- Reviewing the condition of seating modules and all components associated with seats

- Inspection of all hardware

Each inspection has these components, tailored to the specific type of equipment. For more information regarding what to anticipate on maintenance inspections, please contact a team member at FEC.